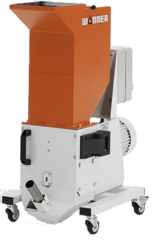

Dynamic – The universal granulator line for massive parts

PRODUCTS

Dynamic

The universal granulator line for massive parts

The Dynamic-Series

The universal granulator for massive parts.

The D-Series is now based on four model sizes:

- D 25.25 with a cutting chamber opening of 250 x 255 mm²

- D 25.38 with a cutting chamber opening of 250 x 385 mm²

- D 25.50 with a cutting chamber opening of 250 x 505 mm²

- D 30.50 with a cutting chamber opening of 300 x 500 mm²

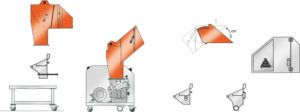

The granulator with standard hopper can be equipped with an additional chute, which can serve as robot in-feed slide or tray for manual hand feed to suit the various feeding options.

The optional sound proof enclosure and a wide range of alternative motors, stands and controls allow the granulator to be tailored to your specific requirements.

The new rotor design with scissor cutting action guarantees a high quality regrind with an extremely low percentage of fines. The sound absorbing feed hopper and the solid cutting chamber made of vibration reducing die casted parts minimises the low noise level, even when granulating heavy parts. The unit is extremely easy to open and to clean, saving time and money.

Even with the optional sound enclosure fitted, access to the cutting chamber can be gained easily via a large door. Based on proven designs, the D Series offers improved productivity and excellent value for money.

- Large cutting chamber with hardened inserts guarantee reduced wear and therefore long life even when processing glass filled materials.

- The rotor design allows for granulation of large parts and awkward sprues.

- Large cutting chamber and scissor cutting action provides low noise levels and good quality regrind with minimal fines.

- Optional integrated sound proof enclosure.

- Controls range from simple contactor to comprehensive diagnostics.

- Compact design and small footprint.

- Cutting knives easily resharpened.

- Tray for hand feed or robot in-feed chute available

- Sack filling box for granulator on central granulating stand.

D-Series granulators either with or without sound deadening enclosure are easy to open, providing full access to the cutting chamber for service or cleaning. The sound deadening enclosure can be opened wide to allow easy approach to the granulator. The cutting chamber can be opened up very easily without the necessity of tools allowing excellent access and sight to rotor, screen and knives. The cleaning of the granulator during a change of colour or material therefore can be very easily done.

| D25.25 | D25.38 | D25.38 Compact | D25.50 | D30.50 | |

|---|---|---|---|---|---|

| Cutting chamber opening: | 250 x 250 mm² | 250 x 385 mm² | 250 x 385 mm² | 250 x 505 mm² | 300 x 500 mm² |

| Rotor- diameter: | 195 mm | 195 mm | 195 mm | 195 mm | 250 mm |

| Rotor- knives: | 12 | 18 | 18 | 24 | 6 |

| Rotor- speed: | 350 / 540 | 350 / 540 | 170 | 350 / 540 | 500 |

| Stator- knives: | 2 | 2 | 2 | 2 | 2 |

| Motor- power: | 4 / 5,5 / 7,5 kW | 5,5 / 7,5 kW | 4 kW | 5,5 / 7,5 kW | 7,5 kW |

| Drive: | V-Belt | V-Belt | Gear | V-Belt | V-Belt |

| Spannung: * | 400 Volt / 50 Hz | 400 Volt / 50 Hz | 400 Volt / 50 Hz | 400 Volt / 50 Hz | 400 Volt / 50 Hz |

| Sieb- lochung: | 4, 5, 6, 8, 10, 12 mm | 4, 5, 6, 8, 10, 12 mm | 4, 5, 6, 8, 10, 12 mm | 4, 5, 6, 8, 10, 12 mm | 4, 5, 6, 8, 10, 12 mm |

| Gewicht: | 380 kg | 430 kg | 430 kg | 480 kg | 550 kg |

| Absaug- behälter Vol.: | ca. 12 l | ca. 17 l | ca. 17 l | ca. 22 l | ca. 22 l |

| Steuerung: | Protective controller * | Protective controller * | Protective controller * | Protective controller * | Protective controller * |

* Power supply:

other voltage available upon request

* Controller:

protective controller with overload release, electrically redundant safety limit switches and safety monitoring device according to EN 12012, various control options available.

4 m connecting cable with CEE plug.

Application profile:

The granulator can be used as beside-the-press granulator to process big, awkward sprues or massiv scrap.

Due to the relatively high throughput these machines can be used as well central granulator.

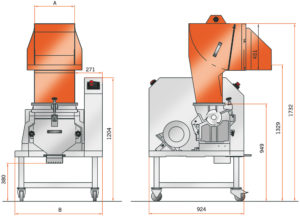

| D 25.25 | D 25.38 | D 25.50 | |

|---|---|---|---|

| A | 870 | 870 | 870 |

| B | 730 | 850 | 970 |

| C | 890 | 890 | 890 |

| D | 270 | 390 | 510 |

| E | 271 | 271 | 271 |

| F | 925 | 925 | 925 |

| G | 1120 | 1120 | 1120 |

| H | 1310 | 1310 | 1310 |

| I | 1655 | 1655 | 1655 |

| J | 380 | 380 | 380 |

All measurements in mm

D-Series: Dimensional drawing High stand

D-Series: Dimensional drawing High stand

Application profile:

The granulator on high stand can be used as compact central granulator to process awkkard sprues or massiv scrap. The regrind can be collected in a sack or a container underneath the granulator, therfore a blower is not necessary even when processing high throughput.

| D 25.25 | D 25.38 | D 25.50 | |

|---|---|---|---|

| A | 380 | 380 | 380 |

| B | 730 | 850 | 970 |

| C | 1200 | 1200 | 1200 |

| D | 270 | 390 | 510 |

| E | 925 | 925 | 925 |

| F | 1330 | 1330 | 1330 |

| G | 1730 | 1730 | 1730 |

All measurements in mm

Videos

The Wanner Dynamic Line

Duration: 02:30 min

This is how the knife change works

for the Wanner Dynamic series

Duration: 05:46 min

D 25.25 with sound proof enclosure

Wanner-Technik Novelty

Application

DOWNLOADS