Compact – The beside-the-press granulator with numerous benefits

PRODUCTS

Compact

The beside-the-press-granulator line with numerous benefits

The Compact Series

The beside-the-press granulator with numerous benefits.

The C-Series is based on three model sizes:

- C 13.20s with a cutting chamber opening of 130 x 200 mm²

- C 17.26s with a cutting chamber opening of 170 x 260 mm²

- C 17.31s with a cutting chamber opening of 170 x 310 mm²

Because of their modular construction, the C Series granulators can easily be adapted to the particular application or the operational needs. Depending on the manner in which the spues are fed in, disposal of the reground material and the injection moulding machine in use, the C Series from Wanner with its many standard components offers optimum solutions which can be adapted to your particular operational requirements.

THE NEW C SERIES IS IMPROVED WITH REGARD TO THE FOLLOWING POINTS:

- Noise level is reduced by up to 4 dB(A) when granulating hard and brittling materials.

- Advanced simplicity of use and ease of cleaning.

- modular building block system enables simple adaptation to any particular application

- only small footprint required due to compact design

- robust motor and gear unit for long life

- significantly reduced noise level due to bevel cut action and reduction of structure born noise through optimized cutting chamber design.

- simplicity of use and ease of cleaning saves downtime and money

- improved ‘pull–in’ action of the rotor for bulky parts and awkward sprues.

- hardened components included within the cutting chamber reducing wear from abrasive materials

- high quality regrind with low dust content due to optimized rotor design. The rotating side disk in the cutting chamber side wall reduces friction and therefore prevents warming up and ultimately degradation of the regrind

- knives easily resharpened without special equipment

- intrinsically safe and sound-damped in-feed hoppers

- variety of controls, from simple protection control to intelligent system controller with volt free contacts and alarm system.

- excellent price-to-performance ratio

- [1] To open the granulator-Take out the suction / sack filling box from the front.

Extremely simple operation - [2] Open the quick release catch. The upper part of the cutting chamber and in-feed hopper is supported on a heavy duty hinge and can be swung completely aside.

- [3] Allows free access to the cutting chamber. The rotor and can be inspected freely and the screen can easily be removed. Undercuts and openings in which material could collect are reduced to a minimum allowing the granulator to be fully cleaned in seconds.

| C13.20s | C17.26s | C17.31s | |

|---|---|---|---|

| Cutting chamber opening: | 130 x 200 mm² | 170 x 260 mm² | 170 x 310 mm² |

| Rotor diameter: | 130 mm | 170 mm | 220 mm |

| Rotor knives: | 9 | 12 | 12 |

| Stator knives: | 2 | 2 | 2 |

| Motor power: | 2,2 kW | 3 kW / 4 KW | 4 kW |

| Power supply: * | 3×400 Volt/50 Hz | 3×400 Volt/50 Hz | 3×400 Volt/50 Hz |

| Screen size: * | 3-8 mm | 3-8 mm | 3-8 mm |

| Weight (standard): | 135 kg | 155 kg | 165 kg |

| Suction box volume: | ca. 4 l | ca. 6 l | ca. 7 l |

| Suitable for glass fiber materials: | Standard configuration | Standard configuration | Standard configuration |

| Controller: * | protective controller* | protective controller* | protective controller* |

*Power supply:

other voltage available upon request

*protective controller:

protective controller with overload release, electrically redundant safety limit switches and safety monitoring device according to EN 12012, various control options available.

4 m connecting cable with CEE plug.

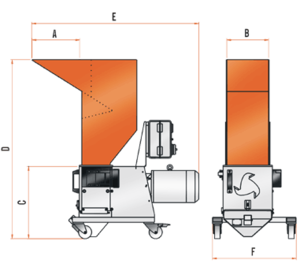

C-Series: Dimensional drawing standard

Application profile:

Application profile:

Because of its low height especially well suited for loading by conveyor belt with separating device or for feeding by hand from a sitting position.

Evacuation should be by hopper loader or central vacuum material handling system – manual emptying is also possible.

| C 13.20s | C 17.26s | C 17.31s | |

|---|---|---|---|

| A | 230 | 290 | 290 |

| B | 200 | 255 | 310 |

| C | 400 | 440 | 480 |

| D | 890 | 1090 | 1170 |

| E | 750 | 1020 | 980 |

| F | 410 | 510 | 510 |

All measurements in mm

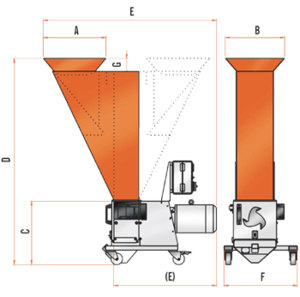

C-Series: Dimensional drawing Sprue picker hopper

Application profile:

Application profile:

Especially well suited for loading by sprue picker or robot. Because of the long straight input path of the hopper even very long sprues do not present a problem.

Evacuation should be by hopper loader or central vacuum material handling system. (Hopper can be rotated through 180°.)

| C 13.20s | C 17.26s | C 17.31s | |

|---|---|---|---|

| A | 420 | 435 | 435 |

| B | 370 | 410 | 450 |

| C | 400 | 440 | 480 |

| D | 1390 | 1430 | 1470 |

| E | 1035 | 1200 | 1210 |

| (E) | 660 | 770 | 770 |

| F | 410 | 510 | 510 |

| G | 90 | 90 | 90 |

All measurements in mm

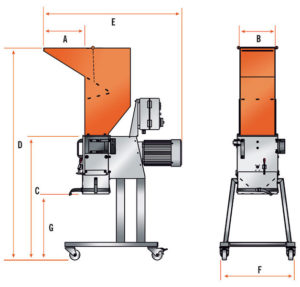

Application profile:

Application profile:

Especially well suited when the recycled material is not disposed of automatically but is collected in sacks or containers.

Also suitable for loading by sprue picker or robot. The sack filling box can be replaced at any time with a suction box for automatic granulate removal.

| C 13.20s | C 17.26s | C 17.31s | |

|---|---|---|---|

| A | 230 | 290 | 290 |

| B | 200 | 255 | 310 |

| C | 890 | 910 | 950 |

| D | 1380 | 1560 | 1640 |

| E | 755 | 1020 | 980 |

| F | 550 | 550 | 650 |

| G | 495 | 485 | 485 |

| H | 130 | 130 | 130 |

All measurements in mm

C’s Standard

Wanner-Technik Novelty

Application

DOWNLOADS

Granulator C17.26s

Standard hopper, on highstand, with suction box

Granulator C17.26s

Standard hopper (C2-00)