CLE – The particularly quiet universal granulator

PRODUCTS

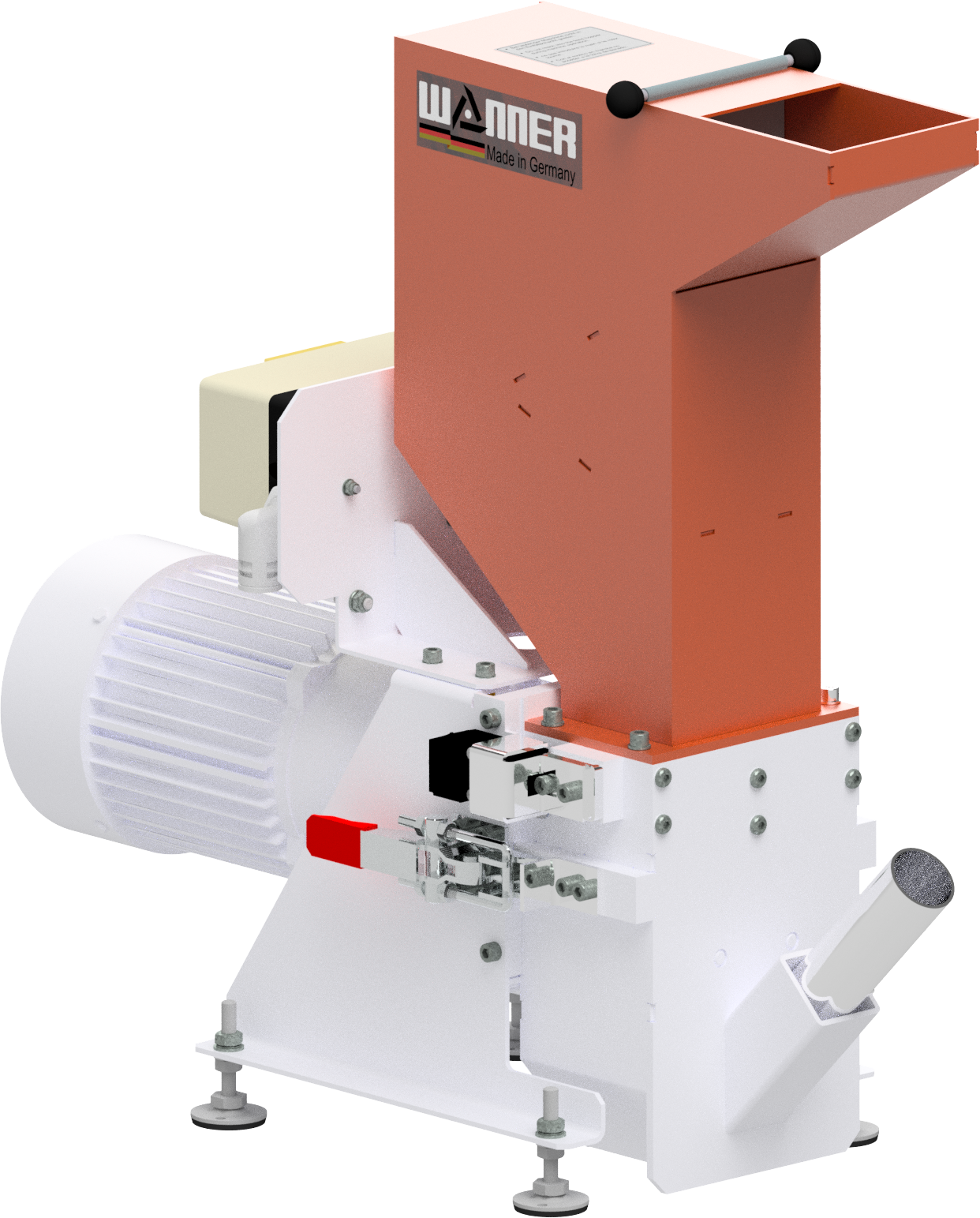

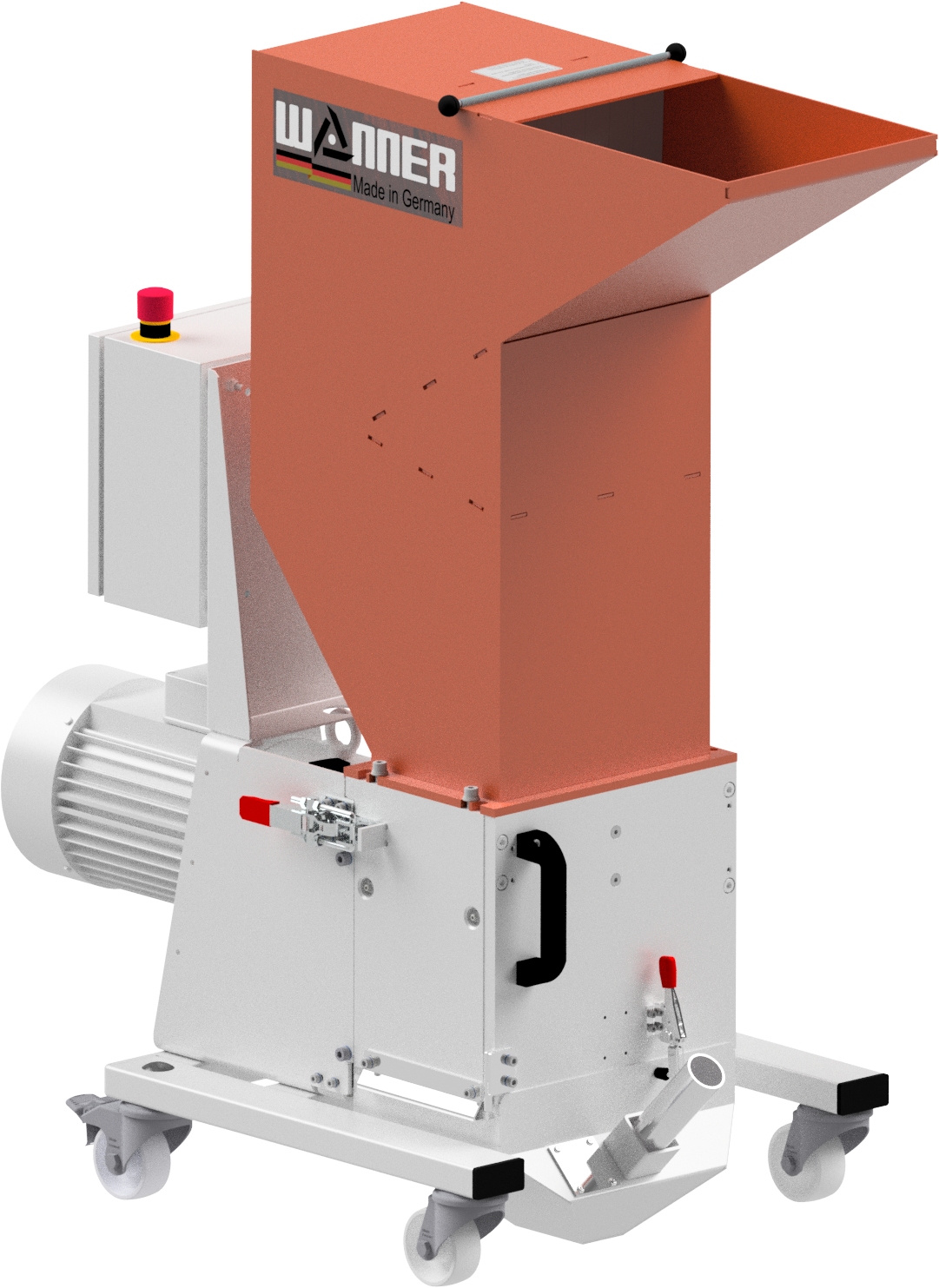

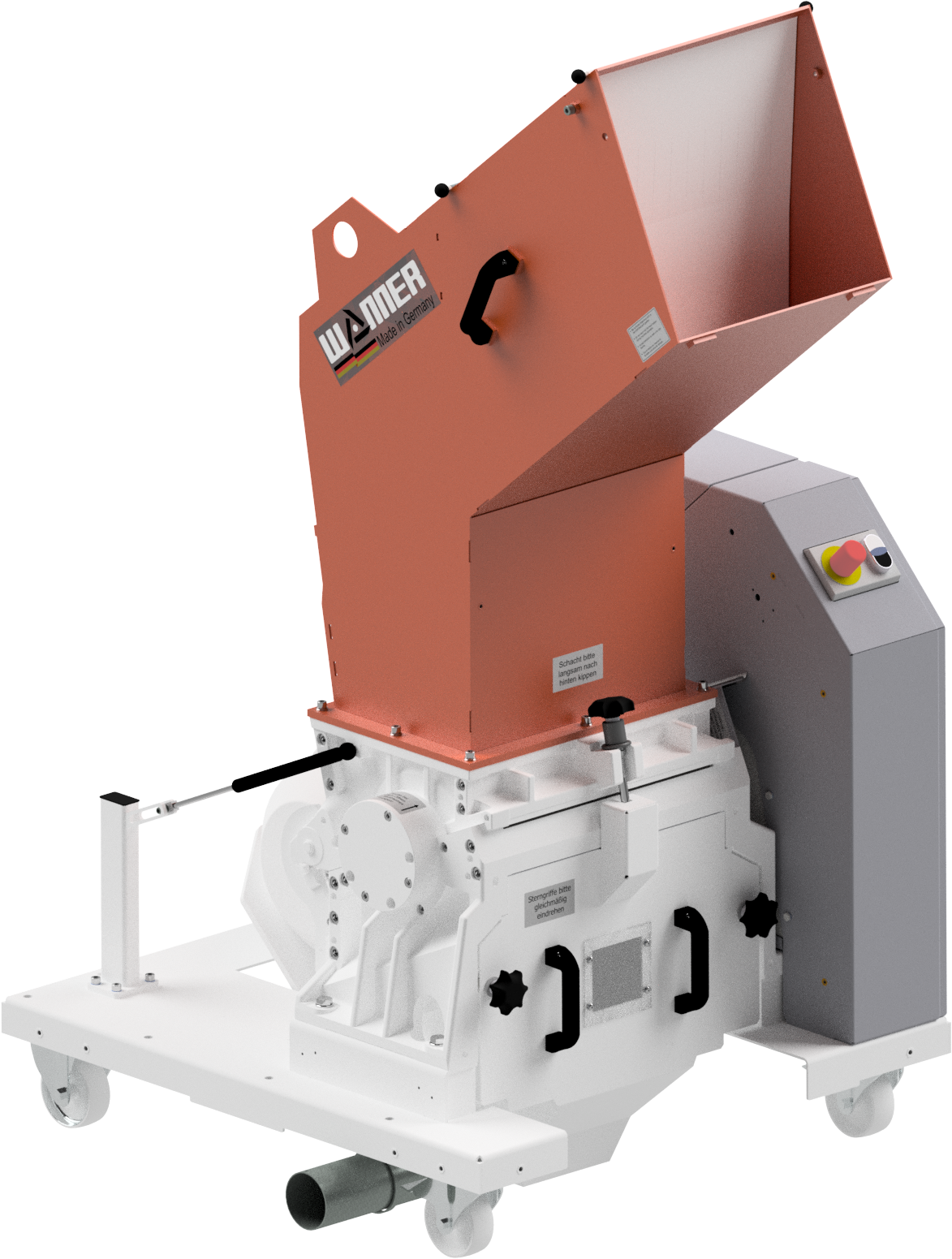

CLE

The particularly quiet universal granulator

The Compact-Low-Noise-Emission Granulator

The particularly quiet universal granulator

When processing hard and brittle, solid GF-reinforced sprues, usual knife-type granulators are often quite noisy. Usually, this noise problem is adressed by using an integrated sound enclosure mounted to the granulator. However, this enclosure often restricts accessibility during cleaning and requires additional space.

When developing the CLE series, we took a different approach to the noise problem: We have reduced the noise emission by taking constructive measures on the cutting chamber and the chassis, to dampen the structure-born noise and vibrations.

The results can be heard and seen! Depending on the processed material, the noise reduction improves significantly, even better than using an integrated soundproof enclosure. As always, the cutting geometry adopted from our C-series delivers a very high-quality, uniform, and low-dust regrind. The CLE granulator is also available with the Green-Line energy-saving control, which guarantees a particularly economical operation. Would you like to hear a little sample?

CLE: Advantages

- Universally applicable for various plastics and a wide range of demands

- Significantly reduced noise emission when grinding brittle, hard GF-reinforced plastics compared to other available granulators

- Comparison measurements with other available beside-the-press granulators show a reduction of the sound level by up to 10 dB(A), which is approximately the noise level of a screenless type of crusher granulator

- Many available options allow an optimal adaptation to your requirements

- Easy handling and a good accessibility make cleaning and material changes simple

- High-quality regrind due to an optimized cutting geometry for all plastics – from soft to hard and reinforced

- Low energy consumption – innovative Green-Line control available

- Optimal for demanding applications

| Cutting chamber opening | 230 x 350 mm² |

| Rotor diameter | 170 mm |

| Rotor knives | 12 + 12 |

| Stator knives | 2 + 2 |

| Motor power | 3,0 kW |

| Weight | 340 kg |

| Durchsatz | approx. 45-60 kg/h |

Comparative tests

The noise development when shredding plastics is very dependent on the product to be shredded. We have compared our new Wanner CLE with other available granulators when grinding various materials and have obtained these results:

| Material | Noise reduction* |

| PA 6.6 GF / rod d = 8 mm | -9 dB(A) |

| Sprue ABS / rod d = 8 mm | -5 dB(A) |

| Sprue PP / rod d = 8 mm | -3 dB(A) |

* Noise reduction of the CLE compared to the reference granulator in our tests

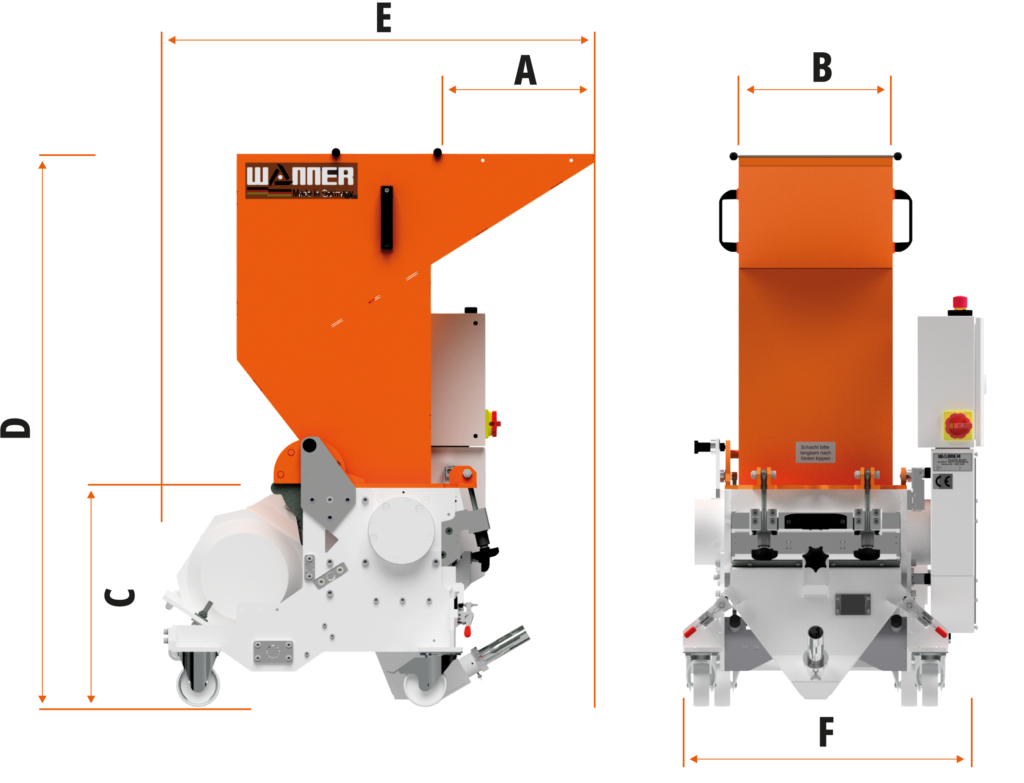

The CLE: Dimensional drawing standard

| A | 300 |

| B | 346 |

| C | 495 |

| D | 1250 |

| E | 979 |

| F | 693 |

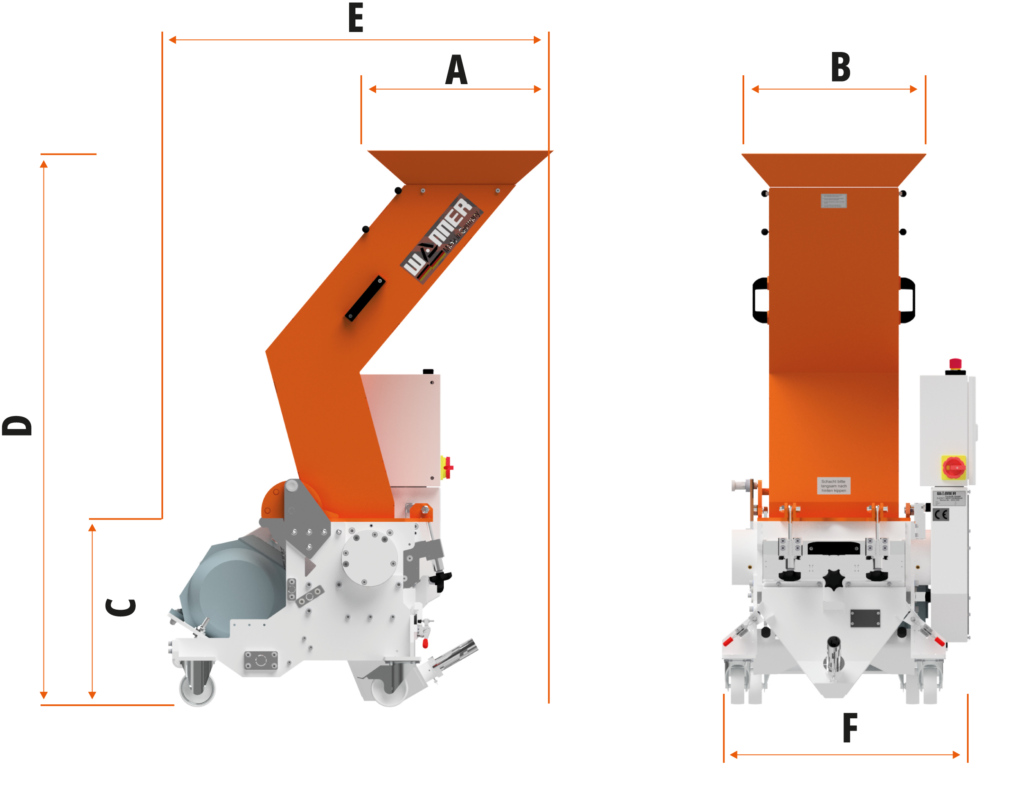

| A | 500 |

| B | 500 |

| C | 495 |

| D | 1488 |

| E | 1035 |

| F | 687 |

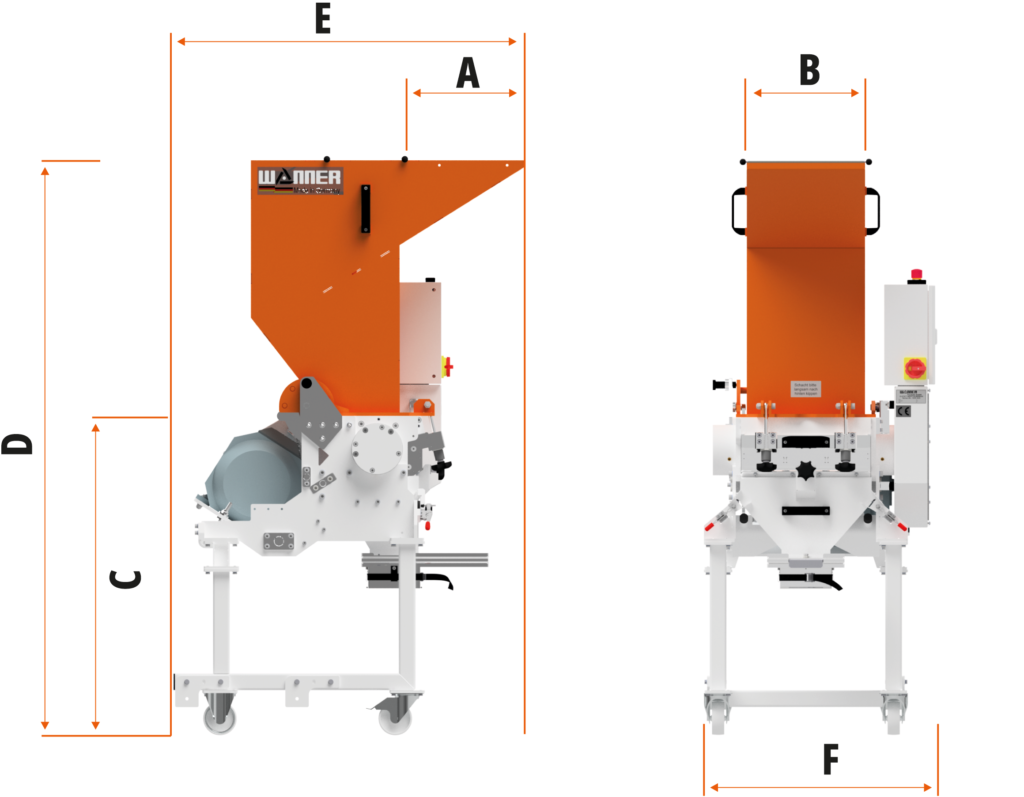

| A | 300 |

| B | 346 |

| C | 943 |

| D | 1698 |

| E | 1038 |

| F | 687 |

Product pictures

We are currently working on a video about the new machine, so check back soon!

Here you can view and download the new CLE brochure: